ETAL Group, world leaders in magnetic components for power and signal applications, has enhanced its R&D centre in Helsingborg, Sweden with an investment in best in class electromagnetic field simulation and modelling software. As a result, ETAL can turn around customer designs much more quickly, using simulation to tune the design allowing optimum performance to be achieved without the need to create multiple prototypes.

According to Martin Carlzon, R&D Manager at ETAL, “Our investment allows us to achieve designs that match customers’ expectations much more closely, and achieve them more quickly at lower cost. Whether the design objective is to deliver a level of performance within a budget, achieve a desired level of efficiency or to push the envelope and create something exceptional, our new tools will move us towards the goal more quickly. When we produce a prototype we do so with confidence that its performance will match the electronic model closely.”

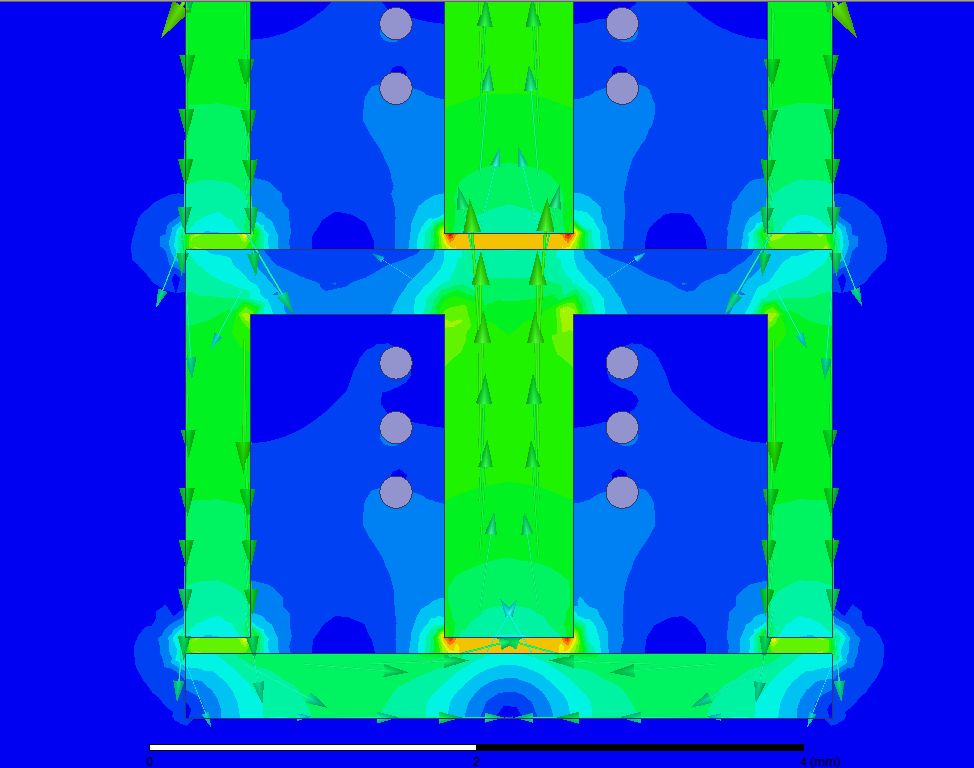

The new ETAL electromagnetic field simulation capability allows their design team to create a very accurate model of a magnetic component within the CAD package. They can try the impact of different materials, wires and air gaps, tuning the design to get as close as possible to the parameters required by the customer. The simulation software uses the finite element method to simulate low-frequency electromagnetic fields in industrial components including 2-D magnetic transient, AC electromagnetic, magnetostatic, electrostatic, DC conduction and electric transient solvers. It will accurately solve for field parameters including capacitance, inductance, resistance and impedance.

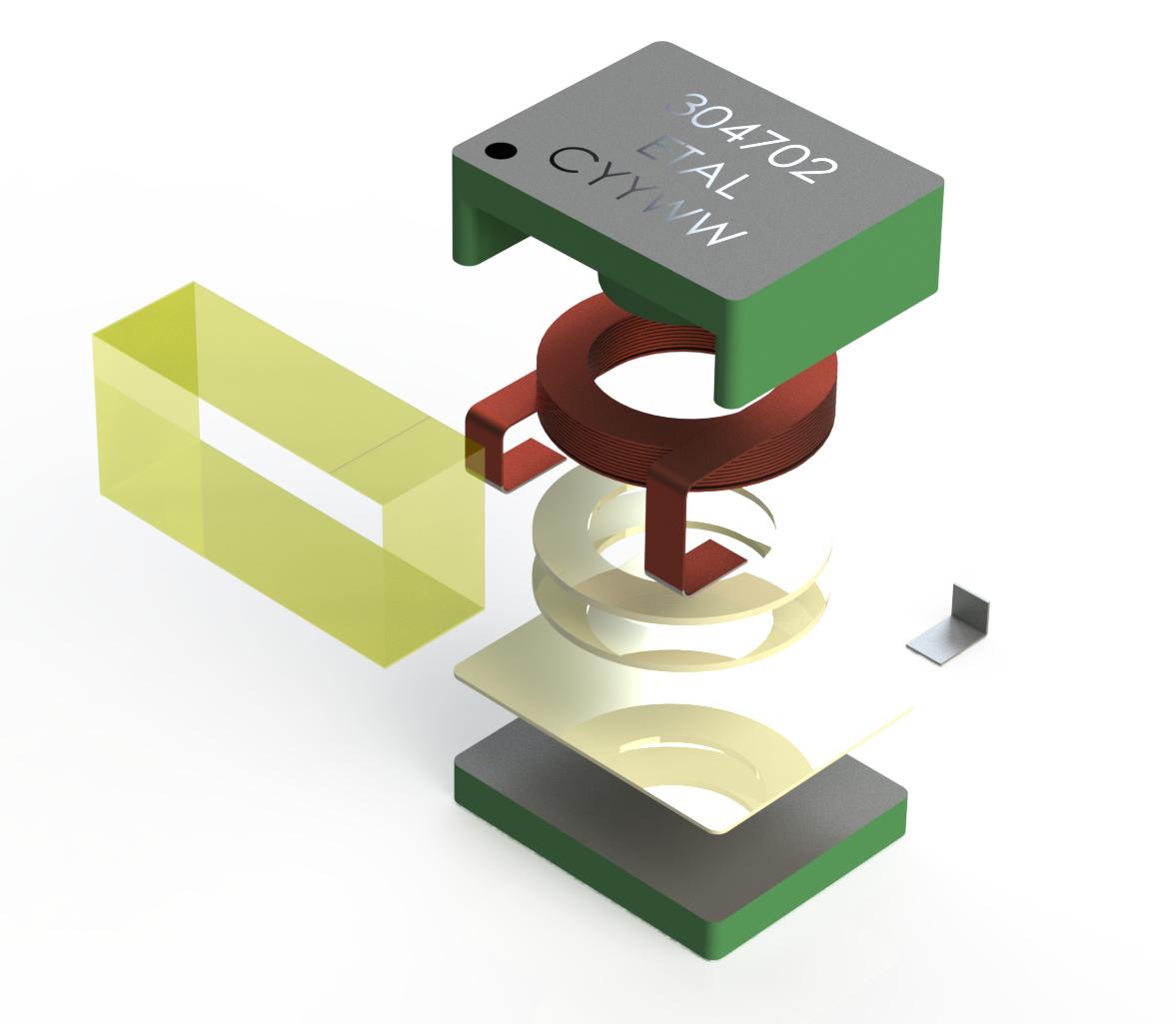

ETAL now also offers its customers the benefit of a full 3D CAD tool suite, giving it the capability to create production level drawings that the customer can readily import into their own suite. They can move forward with the mechanical and electrical design of their system without a physical sample of the finished component.

ETAL Group offers customers a complete design capability for magnetic components, class D amplifiers and on-board or separate switch mode power supplies. Its team at the R&D center in Sweden has more than 50 years’ experience of magnetic design and is well versed in EMI and safety regulations in major markets including Europe and the US. Once the design specification is finalised, ETAL Group can build a prototype, and offers extensive qualification capabilities including climate and humidity tests and reflow process tests. For audio products, Audio Precision is available to evaluate audio performance.

ETAL manufactures and sells in-house developed high-performance magnetic components such as transformers and inductors, which are used in AC/DC converters, DC/DC converters and signal applications. Target markets include the telecom, power technology, automotive, industrial and defence industries. The majority of components are custom-designed for specific applications, but ETAL also offers a range of standard components. It also develops and manufactures the Anaview range of high-quality Class D amplifiers for the global audio industry.